Introduction of hydraulic jack or hydraulic cylinder

Hydraulic jacks are tools that convert hydraulic power into mechanical power in the hydraulic circuit, which can use the hydraulic energy produced byhydraulic pump convert into linear or angular movement with the help of a cylinder, which are a very important part of the machine's hydraulic system and are often exposed to extreme loads and operating conditions. قطرThe cylinder is the most important factor that determines the power of the cylinder.

How does a hydraulic cylinder work?

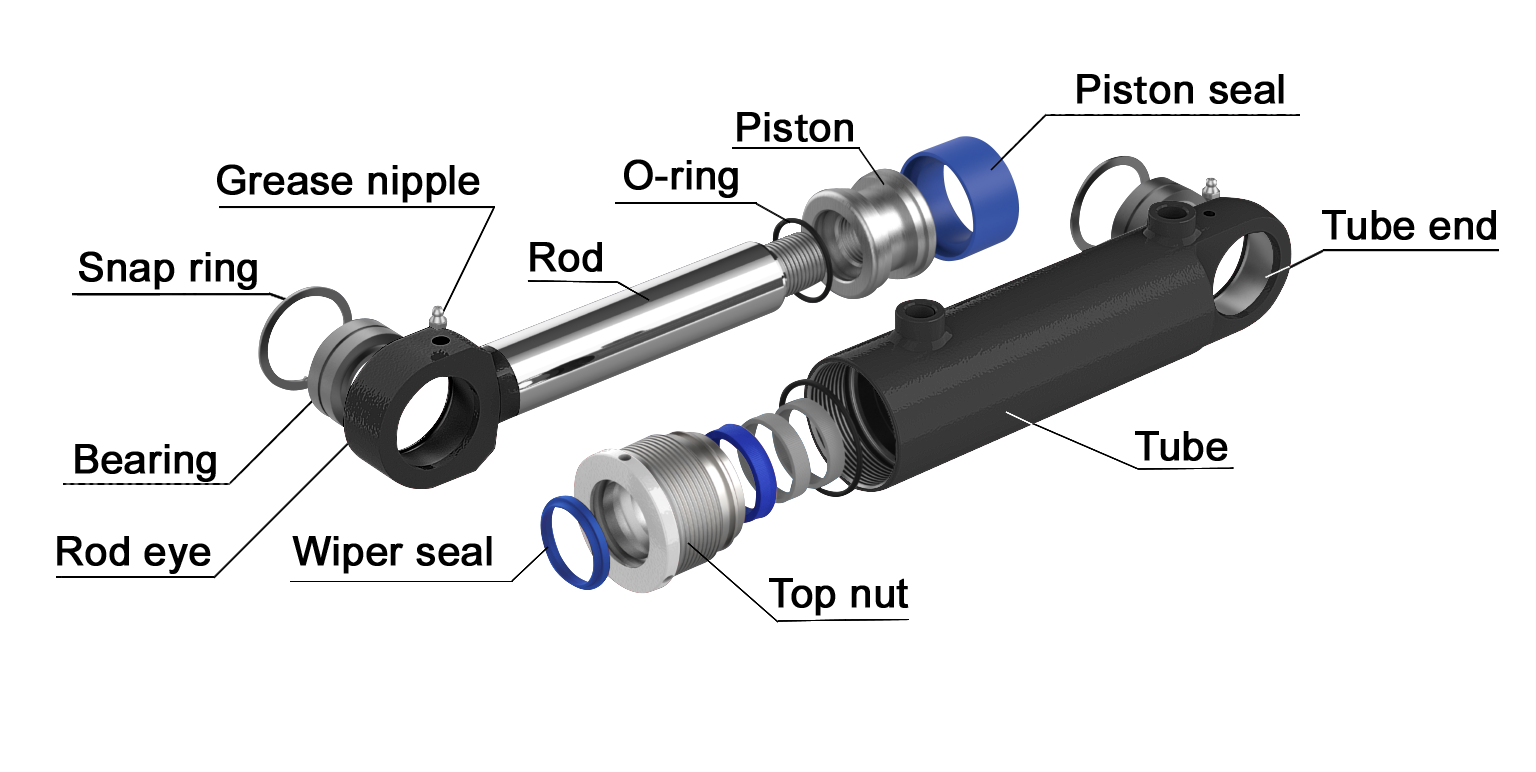

The structure of all types of jacks

Structurally, hydraulic jacks are a tube inside which a manufactured bypiston There is a rod. Piston and cylinder tube are the main components of the structure. The movement of the piston occurs due to the increase in the pressure of the working fluid.

Jacks are also different in construction and are used in different dimensions and types, one-way and two-way in the market.

Hydraulic jack structure

To order hydraulic jack accessories Here click

Hydraulic jacks manufactured by Turk Hydraulic Company

- Lifting hydraulic jack

- Two-way hydraulic jack

- Telescopic hydraulic jack

- Single-sided hydraulic jack

- Reel hydraulic jack

- Hydraulic jack with two shaft ends

- Hydraulic spring return jack

Hydraulic jack function

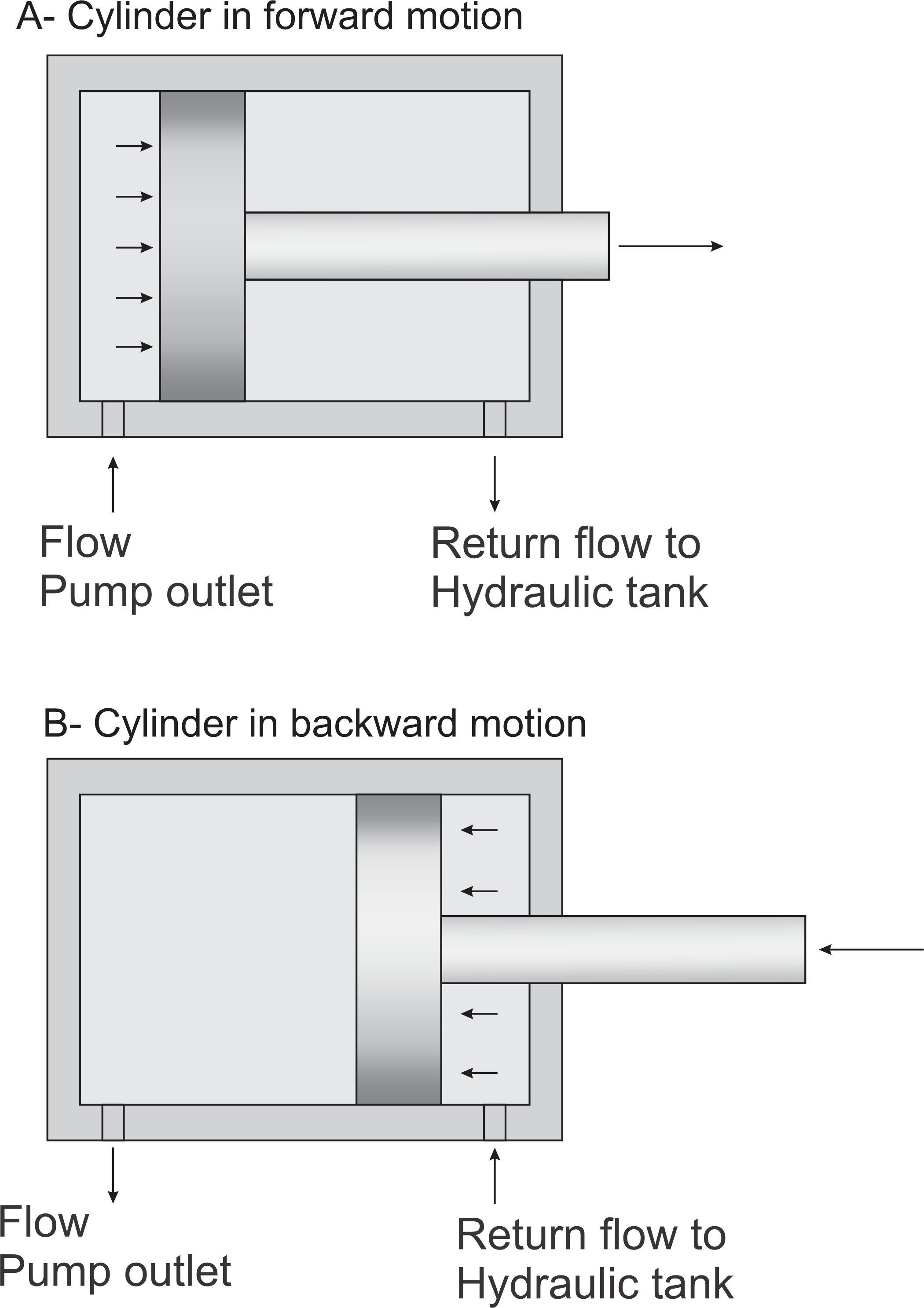

The operation of a hydraulic jack is shown in the figure below. For the piston rod to move forward, fluid flow must be connected cap Drive the hydraulic jack pack. In order for the piston rod to move forward, it is also necessary to drain the fluid inside the hydraulic jack through the cap connection and direct it to the hydraulic tank. For the piston to move backward, the fluid flow from the pump must be directed to the connection of the front cover, and the fluid inside the cylinder must exit from the connection of the rear cover and be directed to the hydraulic tank. As shown in the figure below, the surface of the piston moves forward. The rear is lower than the piston surface when moving forward. Because the area of the piston rod is subtracted from the effective area of the piston. For this reason, the force in the forward movement will be more than the backward movement.

The operation of a hydraulic jack

Jack flange from the front

hydraulic jacks The front flange is able to apply force in both directions, which means that by applying pressure to each sidepiston In a jack, the force is created in that direction. Each hydraulic jack consists of a body, end caps, piston and piston rod. Applying fluid pressure to each side of the piston causes the piston to move to one side inside the body of the hydraulic jack. The piston rod that comes out from the end of the hydraulic jack transfers the power to the output mechanism of the system.

The fluid is directed into the hydraulic jack through the connections installed on the openings of the covers.

The size of a hydraulic jack usually indicates the internal diameter of the jack body. inside of cap Piston rod guides, sealing rings, seals and bearings are also installed. The sealing ring is necessary to create enough pressure in the jack. Bearings are necessary to restrain the lateral force to the piston rod and the dust collector ring to prevent contamination from entering the hydraulic jack. The sealing and dust collector rings are usually rubber. Bearings are usually made of soft metals such as bronze, hard plastic or composite. The internal surface of the jack and the surface of the piston rod must be completely polished to prevent wear and tear and damage of the sealing rings.

Construction of a hydraulic jack

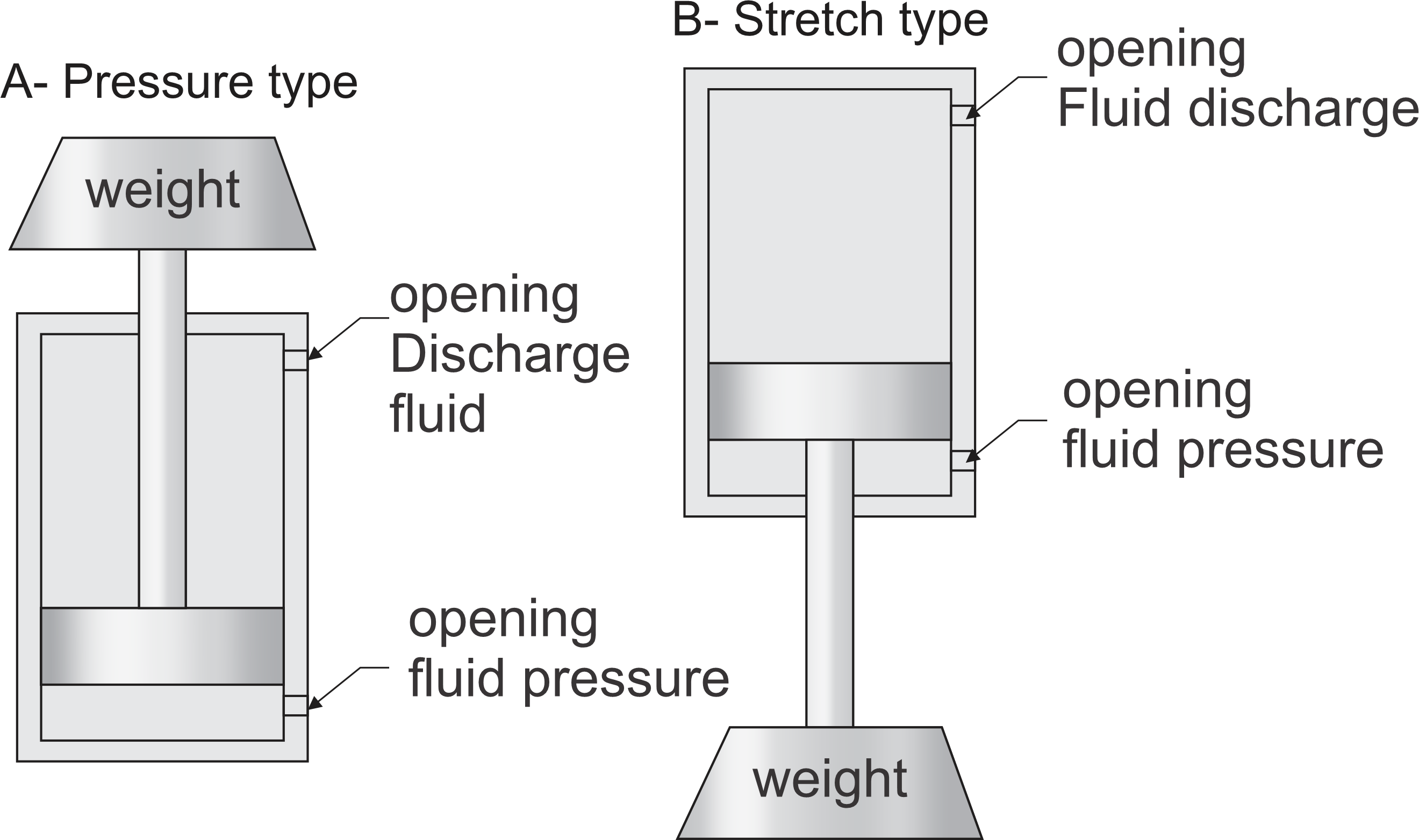

This type of jack is the most common type of hydraulic jack. Of course, in industrial equipment, different types of jacks are used. The single-action jack applies force in only one direction and when the fluid pressure is cut off, it automatically returns to its initial state. Hydraulic jack can be of tension or compression type. In a pressure hydraulic jack, the jack applies force when moving forward, and as soon as the pressure is removed from the cylinder, it will automatically move back. Hydraulic Jack is a traction tool that applies force when moving backwards and will automatically move forward as soon as the pressure is removed from it. The return movement in a single-action hydraulic jack may be done by an internal spring, or an external weight. In hydraulic jack, the pulling type moves the piston backward due to fluid pressure, and the weight is pulled up. can be In this type of jacks, the opening of the front cover, the opening of the fluid pressure and the opening of the rear cap open to the open air. By removing the fluid pressure, the jack will automatically move forward and the fluid entered into the jack will be discharged to the hydraulic tank.

Price list of hydraulic jacks

Hydraulic cylinder power

Hydraulic cylinders, the flow of fluid output from the pump to move linearly piston(and why) they convert. The movement of the piston rod does mechanical work by moving a load. If something resists the movement of the piston. The pressure must increase in the cylinder so much that the resulting force overcomes the resistance factor. If the maximum pressure of a system is not enough to overcome the load, the cylinder will not be able to move and no movement will occur despite the force. When the piston can move the load by applying force, it can be said that power has been transferred.

Uses of hydraulic jack

In general, hydraulic jacks can be used to lift, lower, move and lock. For example, they are used in cranes, hoists, tools, forklifts, road construction equipment, mining and agricultural equipment, elevators, dump trucks or even in airplanes.

The advantages of using a hydraulic lift jack

Using elevator hydraulic jack in the design and installation of the elevator in the building reduces the space required for the well by 12%.

Elevators that use a hydraulic jack, compared to traction elevators, do not need a motor room, and the required dimensions are somewhat smaller than the traction type for installation.

Two-stage and two-stage hydraulic jacks are a suitable option for places with limited well drilling. This type of hydraulic jack is assembled as a separate shaft and piston at the installation site.

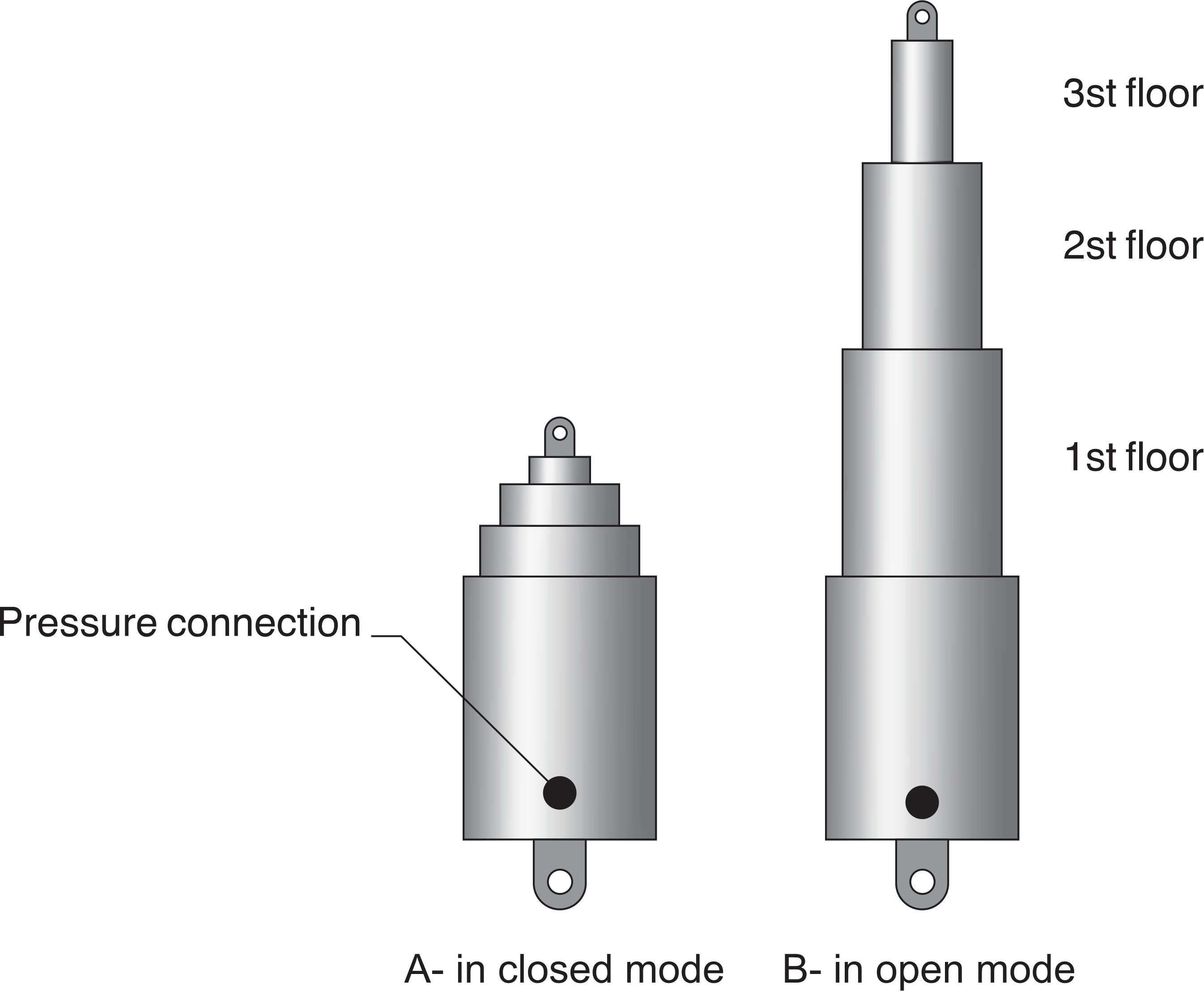

Telescopic hydraulic jack

Each layer of telescopic cylinders is a steel shell that is placed in the shell of the previous layer. Telescopic jack shown in the picture below is a three-story cylinder. Of course, the standard types of these cylinders have up to five floors. One of the uses of telescopic jack is to lift the load part of dump trucks. The length of this cylinder when opened should be large enough to deflect the load part of the truck by 60-70 degrees, and also in the closed state, it should be short enough to easily fit horizontally under the load part. Telescopic cylinders are available in two types, single-acting and double-acting. Telescopic double cylinders cannot produce significant force in the backward movement, because the effective area of the piston in the front of the cylinder is too small. Telescopic cylinders are more expensive than standard cylinders due to their complex structure. The double cylinder with double rod is a type of double hydraulic cylinder whose piston rod is protruding from both sides. By connecting the rods piston , to two different mechanical mechanisms, useful work can be obtained from it in every forward or backward movement, and therefore the efficiency of such cylinders in their specific applications is very good. Due to the double bearing in double rod cylinders, these cylinders can withstand more lateral loads.

Construction of a hydraulic jack

We have been making two-way hydraulic crack cylinders for various types based on customer's drawings for several years Hydraulic equipment And we produce different operating conditions. Our customers mostly order hydraulic and lifting jacks with special designs and different sizes and types.

Our main priorities in work are high quality, reasonable price, stability and success of customers in realizing their projects. The success of our customers is also our success.

Our experts can not only help you choose the right tool for your application, but also provide expert advice. Contact us for more information.

Related products